Solenoid valve working principle

Solenoid valves play a crucial role in various industrial applications, controlling the flow of fluids and gases. These valves are widely used in industries such as manufacturing, oil and gas, automotive, and more. This section provides a definition of solenoid valves and highlights their importance in industrial processes. Furthermore, an overview of the working principle of solenoid valves is discussed, shedding light on how these devices operate to regulate the flow of media.

Components of Solenoid Valves

Solenoid coil

The solenoid coil is an essential component of the solenoid valve. It is an electromagnetic coil wound around a bobbin. When an electric current passes through the coil, it generates a magnetic field.

Plunger or armature

The plunger or armature is a movable component within the solenoid valve. It is attracted or repelled by the magnetic field produced by the solenoid coil. The movement of the plunger controls the opening and closing of the valve.

Valve body and seat

The valve body and seat form the main structure of the solenoid valve. They provide the housing for the internal components and create a seal when the valve is closed, preventing the flow of fluid or gas. The design of the valve body and seat can vary based on the specific application and desired flow characteristics.

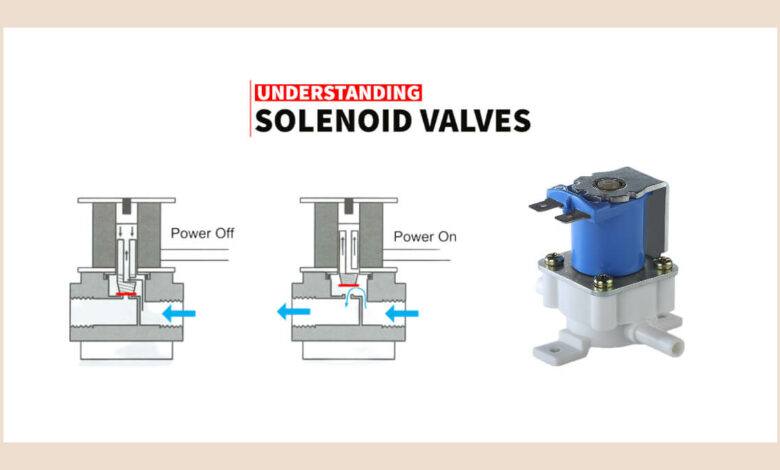

Operation of Solenoid Valves

A. Energized State

In the energized state, an electric current flows through the solenoid coil, creating a magnetic field. This magnetic field causes the plunger or armature to move towards the valve body, overcoming the force of any springs or other mechanisms. As a result, the valve opens, allowing the flow of fluid or gas through the valve.

B. De-energized State

In the de-energized state, when the electric current to the solenoid coil is turned off, the magnetic field dissipates. Without the magnetic force, the plunger or armature returns to its original position under the influence of springs or other mechanisms. As a result, the valve closes, blocking the flow of fluid or gas.

The operation of solenoid valves relies on the precise control of electric current to the solenoid coil, which determines the position of the plunger and, consequently, the opening or closing of the valve.

Types of Solenoid Valves

2-way Solenoid Valves

2-way solenoid valves have two ports: one for the inlet and one for the outlet. They are commonly used for simple on/off applications. One example of a 2-way solenoid valve is the model XYZ-200, which is suitable for controlling the flow of water in irrigation systems.

3-way Solenoid Valves

3-way solenoid valves have three ports: one for the inlet, one for the outlet, and one for exhaust or venting. They are often used in applications where fluid diversion or mixing is required. An example of a 3-way solenoid valve is the model ABC-300, which is used for controlling the flow of air in pneumatic systems.

4-way Solenoid Valves

4-way solenoid valves have four ports: two for the inlet and outlet and two for exhaust or venting. They are commonly used in applications that require the control of two separate fluid circuits. The model DEF-400 is an example of a 4-way solenoid valve used in hydraulic systems to control the movement of cylinders.

These different types of solenoid valves offer versatility in controlling the flow of fluids or gases, allowing for precise and efficient operation in a wide range of industrial applications.

Applications of Solenoid Valves

Fluid Control Systems

Solenoid valves find extensive use in fluid control systems across various industries. The XYZ series solenoid valves are commonly employed in water treatment plants to regulate the flow of liquids and ensure efficient operation.

Pneumatic Systems

In pneumatic systems, solenoid valves play a crucial role in controlling the flow of compressed air. The ABC series solenoid valves are specifically designed for pneumatic applications, such as in assembly lines and automation processes, ensuring precise and reliable air control.

HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems utilize solenoid valves for efficient temperature and humidity control. The DEF series solenoid valves are widely used in HVAC systems to regulate the flow of refrigerants, ensuring optimal cooling or heating performance.

These specific series of solenoid valves demonstrate their suitability and reliability in their respective applications, offering precise control and enhancing the overall functionality of fluid control systems, pneumatic systems, and HVAC systems.

Factors to Consider when Selecting Solenoid Valves

Operating Conditions

When selecting solenoid valves, it is crucial to consider the specific operating conditions. The Burkert solenoid valves, known for their high-quality construction, offer excellent performance even in challenging environments, such as high temperatures or corrosive atmospheres.

Flow Requirements

Different applications require varying flow rates and pressures. The extensive range of Burkert solenoid valves provides options that can handle a wide range of flow requirements, ensuring optimal performance and precise control over fluid flow.

Voltage and Power Requirements

The voltage and power requirements of solenoid valves should align with the available power supply. Burkert solenoid valves are available in different voltage options, allowing compatibility with various power systems and ensuring seamless integration into existing setups.

Compatibility with Fluids

The compatibility of solenoid valves with specific fluids is crucial to ensure reliable operation. Burkert solenoid valves are engineered to work with a wide range of fluids, including water, gas, oil, and corrosive substances, offering excellent chemical resistance and long-lasting performance.

By considering these factors and opting for Burkert solenoid valves, users can ensure optimal performance, reliability, and compatibility in their fluid control applications.

Maintenance and Troubleshooting of Solenoid Valves

Regular Maintenance Procedures

It is important to follow regular maintenance procedures to ensure the continued performance and longevity of solenoid valves. These may include inspecting the valves for any wear or damage, cleaning or replacing filters, and lubricating moving parts as necessary. Burkert solenoid valves, known for their reliability, typically require minimal maintenance but should still be inspected periodically.

Common Troubleshooting Tips

In the event of any issues with solenoid valves, there are common troubleshooting tips that can help identify and resolve problems. Some common troubleshooting steps include checking electrical connections, ensuring proper voltage and power supply, inspecting for clogged or damaged valves, and verifying the compatibility of the valve with the fluid being controlled. Burkert provides comprehensive documentation and technical support to assist with troubleshooting and resolving any issues that may arise.

By following regular maintenance procedures and utilizing common troubleshooting tips, users can ensure the optimal performance and reliability of their solenoid valves, including those from Burkert.

In conclusion, solenoid valves are crucial in various industrial applications, providing efficient and reliable control over fluid and pneumatic systems. Understanding the working principle, components, types, and applications of solenoid valves is essential for selecting the right valve for specific requirements. Burkert solenoid valves, known for their high-quality construction and precision, offer reliable performance in demanding environments.

When selecting solenoid valves, factors such as operating conditions, flow requirements, voltage and power specifications, and fluid compatibility should be carefully considered. Regular maintenance procedures and adherence to troubleshooting tips, such as those provided by Burkert, can help ensure the continued optimal performance of solenoid valves.

By harnessing the power of solenoid valves, industries can achieve efficient fluid control, improved automation, and enhanced system performance. With the right selection, installation, and maintenance, solenoid valves can contribute to the overall success and productivity of industrial processes.